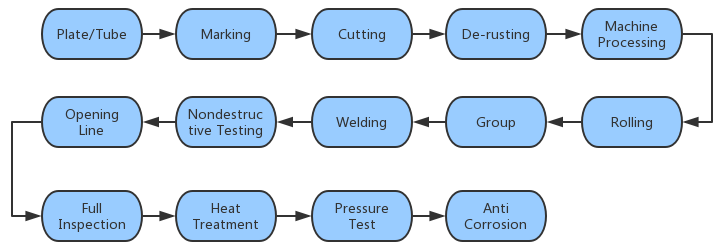

ANSON STEEL provide customers with full steel fabrication services, we aim to provide customers with a convenient one-stop shopping service for boiler and pressure vessel steel. Here are the fabrication options you can have:

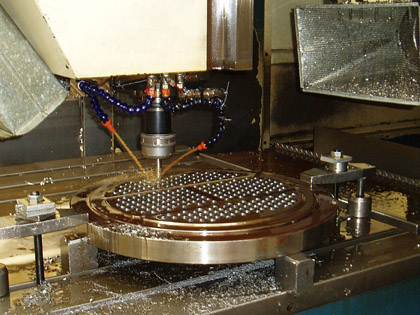

Anson offers drilling and machining service for tube sheet production, drilling is a critical fabrication in manufacturing boiler, cylinder shell and tube exchangers, The accuracy of tube sheet processing, especially tube hole spacing and tube diameter tolerance verticality, finish are greatly affected by the above listed chemical equipment assembly and use performance. ANSON is able to complete this job with high accuracy; we can handle any size and shape of tube sheet or plate, round, half round, rectangular.

Anson STEEL offers tube bending service for heat exchanger project where U shape tube is used, tube can be bend to various raddi configuration including 180°; tube ends are cut and trimmed; tube body is washed before packaged into wooden crate. U shape tube shall go through tests stated by ASME and other specifications for wall thinning, The final quality of U tube is not decided by both the quality of the steel tube and bending process, ANSON has rich experience in providing high quality U tube bending service for end users.

ANSON STEEL offers steel plate cutting service for general needs for customized length and shapes, we can do both precise cutting for steel plate that can be used directly in your pressure vessel project and cut to length with acceptable error. CNC cutting and water jet cutting equipment are used to processing various tube plates, we will fabricate and deliver you the work piece that can be used directly with a given drawing, no extra processing needed.

ANSON STEEL offers steel plate rolling service for projects of boiler and pressure vessels, tanks which steel plate need to be rolled for welding process, steel plate rolling can also be used to produce straight seam welded pipe. ANSON is capable of rolling steel plate of heavy plate with large thickness for C channels, cylinders, tanks, drums, and other round product. Steel plate rolling and forming is one critical process for fabricating these products, usually it is a preparation for steel welding process, which we can do it for you if you need.

ANSON STEEL offers steel welding service for customers, after steel plate and tube are machined according to drawings, welding process is needed in order to fit the separated parts together, for the pipe and tube ends, shell of boiler and pressure vessel, etc, welding methods differs as to the steel material and the pressure requirements, methods include: MIG (GMAW) and TIG (GTAW. Certification included; ASME, AWS, MIL-STD, PED and custom requirements. Customer can choose us to do the welding job for you as the final fabricate process.

ANSON offers beveling fabrication for steel plate and pipes that need to be welded, beveled edges provide weld space for supporting weight and load on machine structures, bevel cutting equipments has various options: laser, plasma, oxyfuel, and waterjet, thermal cutting, abrasive cutting, and machining all take completely different methods to produce bevel cuts on plate, tube, or pipe.

According to the role of different process, ANSON STEEL can provide steel product for following pressure vessel equipments

Container for the physical and chemical reactions of a medium.

Container for heat exchange of medium.

Container for mass exchange of medium,separation of gas purification, solid, liquid and gas.

Container for holding gas or liquid, or for storing medium pressure balance buffer.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!